‘Hey Google, show me the shortest way home.’ or ‘Hey Siri, what’s the weather like today?’. Most people own a smartphone and are using features such as voice-enabled assistants or the portrait mode in smartphone cameras, which have two things in common: They use artificial intelligence (AI) and they simplify our lives.

Digitalization and AI are currently transforming almost every industry – and logistics is one of them. The question of how AI can be used to increase speed, efficiency, and accuracy across the supply chain is key to the evolution of logistics. As a matter of fact, robots and autonomous forklifts are already in use in many warehouses today.

The foundation for AI and AI applications is data. Today, AI has become more popular due to increased data volumes, advancements in algorithms and high computing power combined with storage. With this, meaningful business insight can be derived to support strategic, tactical, and operational decision-making. Based on machine learning and data analytics, optimization potential and cost-saving opportunities can be identified, the operation of supply chains can be improved, and new data-driven services are created.

Thus, AI does not only accelerate a company’s, such as DB Schenker, digital transformation, but it also ensures a long-term competitive advantage within the logistics industry.

The rise of Artificial Intelligence

A commonly used approach to define and describe artificial intelligence (AI) is the concept of a rational agent. This has been borrowed from economic theory. The agent can sense, reason, act to achieve the best expected outcome and learn or adapt.

Alan Turing, the mastermind behind the design of the Turing test, received widespread recognition in 1950, introducing a test used to show if a person can differentiate between a computer and a human. This was when the first theoretical advancements in the field of AI were made, however, ultimately the beginning of the 20th century marks the rise of modern statistics.

1956, AI was established as an independent research field at the Dartmouth Conference. And already in 1957, Frank Rosenblatt invented the perceptron, a concept which nowadays is the smallest unit of a modern neural network. Even at this early stage in the development of AI, the term machine learning was used to describe programs that gave a computer the ability to learn from data.

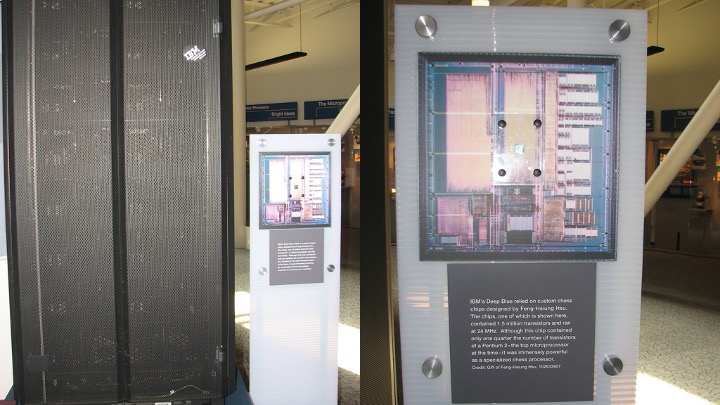

The breakthrough followed in the 1990s with IBM’s Deep Blue computer which beat the world champion at chess. The system was often called AI, although it only used old-fashioned brute force algorithms on powerful hardware and did not apply machine learning, neural networks, or deep learning.

2010 has been the decade of big data, machine learning and AI. Tools like Siri, Cortana, and Alexa have started to make speech interaction with machines ubiquitous. Impressive applications are demonstrating how deep learning outperforms humans in certain areas. IBM Watson beats human Jeopardy champions, AlphaGo beats the world-best Go player. In 2019 the first book was written by a computer. The development of the technology is now at a stage where many industry sectors are implementing artificial intelligence in their businesses.

Leveraging Artificial Intelligence in logistics

In an industry that generates a large amount of data every day, AI methods and applications can improve many areas of the business. For example, in freight, forwarding and contract logistics: demand forecasting, pricing and offer management, network and capacity planning, warehouse and hub analytics, as well as customer analytics are areas impacted.

Estimating demands and flows in the multi-faceted logistics market can be very challenging. It is often characterized by high uncertainty, variability, and unpredictability of political, economic, seasonal traffic, and transport factors. Traditionally, volume and workforce planning were driven by telephone, pen and paper, combined with the gut feeling of very experienced dispatchers for decades. By applying predictive analytics with human experience enables logistics companies to anticipate workflow based on more accurate, data-driven forecasting and thereby achieve higher operational capacity and cost efficiency for short-, medium- and long-term planning.

AI at DB Schenker

DB Schenker, for example, has already implemented AI-based demand forecasting in various business units through large volumes of data collection. In Land Transport, predictive analytics is applied to forecast volumes in terminals. This data-driven support enables improved staff and resource planning with up to 95 percent accuracy on the incoming and outgoing freight volumes which will need to be handled in the upcoming days and weeks.

Ocean Freight trade lane managers are supported by a tool using artificial intelligence whereby they can gain insights into market development trends including forecast volumes and capacities.

Another example for AI-based pricing and offer management is integrated into DB Schenker’s Drive4Schenker platform. It provides load proposals to haulers. The algorithms learn from the data on historical shipments and recommend carriers that are likely to accept offers. It also supports dispatchers in determine costs likely to be realized for trips.

Another complex challenge in logistics is network and capacity planning. State-of-the-art optimization algorithms can analyze the trade-off between several aspects, for example: fleet and inventory capacity, location of warehouses, transportation cost impact, and individual customer constraints. With this data, it is possible to derive the most cost-efficient solution, which can be, as an example, a dedicated fleet setup to a corresponding network scenario or the allocation of postal codes to terminals.

For Schenker Europe, an advanced optimization engine has been implemented and deployed to provide data-driven support for the dispatching process of daily collection and distribution tours around European branches.

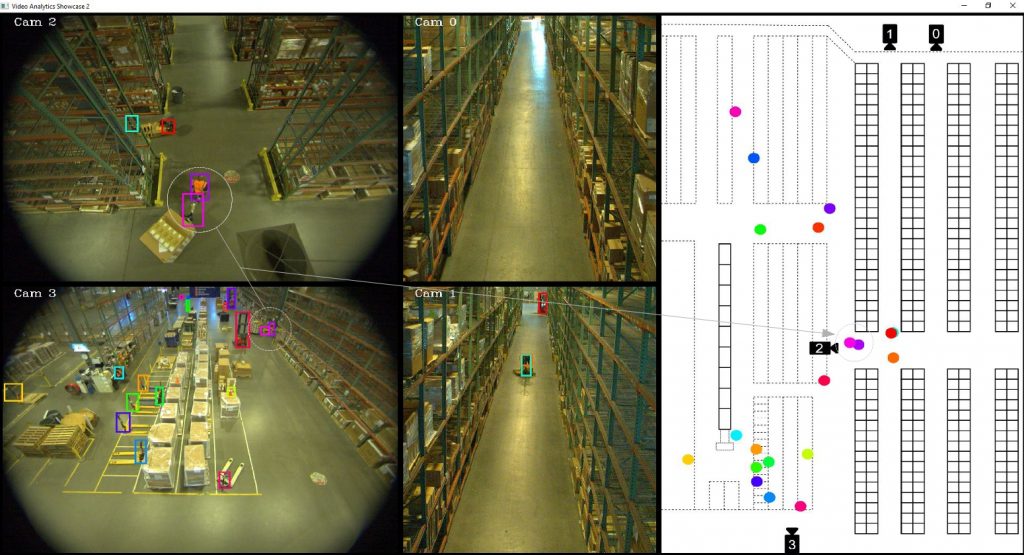

Furthermore, AI in logistics enables innovative analytics opportunities in hubs and warehouses. DB Schenker tested computer vision in warehouses and terminals by applying deep learning algorithms, objects such as pallets, pallet jacks, or forklifts could be detected and tracked in video streams. The position could afterward be translated onto warehouse maps.

At the gateway of Land Transport Terminals, tests started to detect license plates from incoming and outgoing trucks. These tests allow the dispatcher to classify and allocate arriving trucks. The dispatcher is then able to organize the optimal unloading dock or parking position.

Finally, AI can also give valuable insights on customers and detect behavior patterns to forecast or detect changes in their ordering behavior. If there are changes in the usual pattern, logistics providers can anticipate and clarify customer needs.

Challenges of Artificial Intelligence

AI is disrupting the logistics industry and with every change, there come challenges: Digital transformation and AI do not necessarily only meet with acceptance. Even though AI has been proven to have enormous benefit potential, the shift towards digital solutions often goes along with the fear of the workforce being replaced by technology. A sophisticated, structured, and custom-tailored change management, a pioneer spirit as well as time is needed to nurture and thrive digital transformation across an organization.

DB Schenker has dedicated a Global Data Strategy & Analytics department, which is working in close cooperation with the business to leverage the power of AI and drive the shift to a data-driven culture. With custom-tailored AI in-house training, awareness has been enhanced among employees and citizen data scientists are currently trained to further scale AI initiatives across DB Schenker.

Moreover, artificial intelligence touches on juristic challenges. Questions like “How is my data stored? Can the data be traded? What kind of rules are behind the use of the data?” are coming up. Cross-border politics is in need to create a legal and ethical framework on data protection.

Outlook

The use of digital and innovative solutions based on AI is already rolled out in the logistics industry.

And as Henry Ford has said: “If you always do what you have always done, you will always get what you have always got.” AI is an opportunity to make supply chains more efficient and more data-driven to enable it to go far beyond the traditional forwarding business. And we at DB Schenker are getting ready for the future.

Published: June 2021